rockwell hardness tester brinell|disadvantages of rockwell hardness test : supermarket Summary of Brinell Verses Rockwell Hardness. The Brinell and Rockwell methods fall into the group of statistical methods of hardness testing. Each method has its unique purpose, . — Cycling Today (@CyclingTodayEn) February 24, 2024. ED.

{plog:ftitle_list}

Esqueceu sua senha? Não se preocupe! Nos informe seu CP.

Brinell and Rockwell Hardness Conversion Chart - These Conversion Tables presents data in the Rockwell A, B, C, D, E and F hardness range on the relationship among .The typical brinell hardness test uses a 10 millimeters (0.39 in) diameter steel ball .

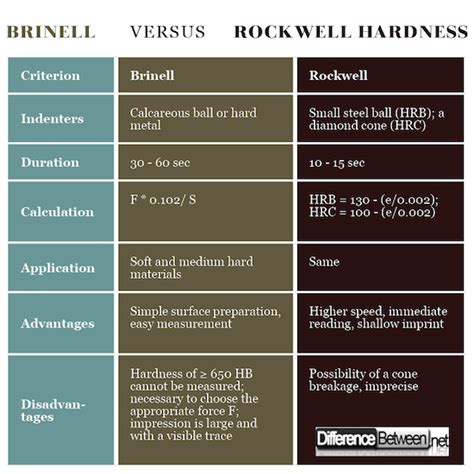

Newage offers a comprehensive range of hardness testers for Rockwell, Brinell, and Microhardness testing. We offer Optical Systems and Software for measurement, data .In this article, our seasoned expert, Lee Mangham, will guide you through the differences between the Brinell and Rockwell hardness tests, including their methods, advantages, differences, and practical significance in evaluating .Summary of Brinell Verses Rockwell Hardness. The Brinell and Rockwell methods fall into the group of statistical methods of hardness testing. Each method has its unique purpose, . Starrett Hardness Testers are precision instruments used to determine the hardness of a material. With a range of models available, including Rockwell, Brinell, and .

rockwell vs brinell hardness test

Brinell test is better than the Rockwell hardness test because it can measure the hardness of though material which is not measurable by another test like Rockwell. Brinell test measures .

реферат на тему влагомеров

Brinell Hardness. Relatively high loads are applied to parts via a tungsten carbide ball in this method. Unlike with Rockwell testing, Brinell tests measure the diameter of the indentation made by the ball, not the depth. A .Using charts and formulas helps designers and engineers convert the hardness value they get from one hardness test to the required hardness test value. For instance, converting from a .

In this context, ATI affirms itself, with its Brinell automatic hardness testers, Rockwell automatic hardness testers and universal automatic hardness testers, which represent the essential tools to guarantee the uncompromising quality .Conclusion. Brinell and Rockwell hardness tests are valuable methods for evaluating material hardness, each with its own advantages and considerations.While the Rockwell test offers simplicity and faster results, the .For instance, converting from a Rockwell hardness test on the C scale (HRC) to a Brinell hardness test value requires using the formula: BHN = 5.970 x (HRC + 104.7). This formula gives an approximate value for the Brinell hardness value, and quality assessment professionals use it to create the conversion tables and charts for instant conversion.

Brinell Hardness. Relatively high loads are applied to parts via a tungsten carbide ball in this method. Unlike with Rockwell testing, Brinell tests measure the diameter of the indentation made by the ball, not the depth. A .Standardized optical hardness testing methods include the Brinell hardness test (ISO 6506, ASTM E10), Knoop hardness test (ISO 4545, ASTM E92, . Vickers and Rockwell. Hardness testing in the low-load range applies when the test load .DEFINITION OF THE BRINELL HARDNESS TEST The Brinell hardness test was originally developed in the late 1800s by the Swedish engineer of the same name. He wanted to find a method to control the quality/hardness of steel. His solution was to press a railway wheel-bearing ball into the material and then measure the size of the mark it left.Shandong Shancai Testing Instrument Co., Ltd./Laizhou Laihua Testing Instrument Factory. is located in beautiful sea city–Yantai. Laizhou Laihua Testing Instrument Factory is an ISO9001 quality system certified enterprise specializing in the production and sales of hardness tester and metallography preparation.

The QualiMag-Auto-RB Automatic Magnetic Brinell & Rockwell Hardness tester follows the conventional Brinell & Rockwell hardness testing method, similar to benchtop hardness testers, ensuring test accuracy and adherence to ASTM E10, ASTM E18, ASTM E110; ISO6506, and ISO6508 standards. Fixed securely with a magneThis article details the Brinell to Rockwell hardness conversion chart, which explains how the test results of one scale can be translated into another. + 86 755 61301520 [email protected] easy to use hardness testing software supports the operator with single tests, as well as complex test tasks. Hardness testing according to current standards. Our DuraVision series offers a wide load range from 0.3-250 kg or from 3-3,000 kg for test methods including Vickers, Brinell, Rockwell, Knoop, plastics testing and carbon testing.

A chart is then used to convert the averaged diameter measurement to a Brinell hardness number. Test forces range from 500 to 3000 kgf. A Brinell hardness result measures the permanent width of indentation produced by a carbide indenter applied to a test specimen at a given load, for a given length of time.Hardness is the property of a material that enables it to resist plastic deformation, usually by penetration. However, the term hardness may also refer to resistance to bending, scratching, abrasion or cutting.

The Brinell hardness is designated by the most commonly used test standards (ASTM E10-14 [2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide). In former standards HB or HBS were used to refer to measurements made with steel indenters.The Phase II hardness tester floor stands are sturdy, heavy metal cabinets for securing your Rockwell, Brinell or Vickers hardness tester. The 900331-STAND is supplied with adjustable feet, a locking door, one drawer for storage of smaller parts .Hardness Methods: The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth of penetration. Rockwell Hardness The Brinell hardness test involves indenting a material with a hard sphere under a specific load. Two diameters (x and y Starrett Hardness Testers indicate the hardness of a material, usually by measuring the effect on its surface of a localized penetration by a standardized rounded or pointed indenter of diamond, carbide, or hard steel. . With a range of models available, including Rockwell, Brinell, and Vickers testers, Starrett offers the perfect tool for .

The DuraVision universal hardness testers for standard load ranges of 0.3-250 kgf or 3-3,000 kgf can be used for Vickers, Knoop, Brinell, and Rockwell tests, as well as for carbon and plastics testing.All methods are covered by the ISO .High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing Like the Brinell, Vickers, Knoop, Scleroscope and Leeb tests - all of which fall in the general category of indentation hardness tests - the Rockwell test is a measure of the resistance .

The Rockwell hardness test can be used to determine the hardness of metals like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. Read More Brinell Hardness Test for MetalsWith a Rockwell hardness tester, you can measure the residual indentation depth created by the indenter using a differential depth method. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material being tested. . Non-standard methods in Brinell HBT in a load range of 294-1,839 N (30 .KB Series Brinell Hardness Tester. The Newage KB Series is a popular, manually-controlled Brinell hardness tester that meets ASTM E-110. This lightweight, portable tester is ideal for virtually any size or shape of metal specimen.Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load).

To wrap up, knowing the best-suited hardness test of the three, Rockwell, Brinell, and Vickers, for your hardness test will require that you understand the determining criteria for employing any hardness test. In the final analysis, the type of material and the environment where the test will take place will significantly determine the best .E-10 Standard Test Method for Brinell Hardness of Metallic Material; E-18 Standard Test Method for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Material; E-92 Standard Test Method for Vickers Hardness of Metallic Material 1kgf to 120kgf; E-103 Rapid Indentation Hardness Testing of Metallic Material

In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested. CMX1000 Portable Hardness Tester Rockwell Brinell Vickers CIMETRIX. Price: 5.00 9.95. Brand: CIMETRIX Product Code: CMX1000 Availability: In Stock Condition: New Add to Wish List Add to Compare | Write a review. Share. Description Metals Probes Reviews (0) CMX1000 Portable Hand Held Hardness Tester. . High Accuracy: Delivers precise hardness testing with an accuracy of +/- 0.5% and repeatability accuracy of +/- 4L units. Versatile Testing: Compatible with multiple hardness scales including Rockwell, Brinell, Vickers, and Shore for diverse applications.

Universal hardness testers are designed for hardness testing according to Brinell, Vickers, Rockwell and Knoop, as well as plastics testing and carbon testing.To cover all of these test methods, the universal hardness testing machine supports a wide load range. ZwickRoell universal hardness testers therefore provide a flexible solution with a load range from 0.3 to .

Visita el centro de ayuda. Desde el portal Mi Tigo podrás recargar minutos, consultar tu consumo de datos, realizar pagos en línea o pagar tu factura Tigo. Haz clic y entra.

rockwell hardness tester brinell|disadvantages of rockwell hardness test